Intumescent fireproof coating for steel structure

Product Classification:

Intumescent fireproof paint

Product Summary:

The fire retardant coating is a water-based intumescent fire retardant coating, which has the characteristics of thin layer and highadhesion.

keywords:

Best Intumescent Fireproof Coating For Steel Structure

Intumescent fireproof coating for steel structure

Intumescent fireproof coating for steel structure

PRODUCT INTRODUCTION

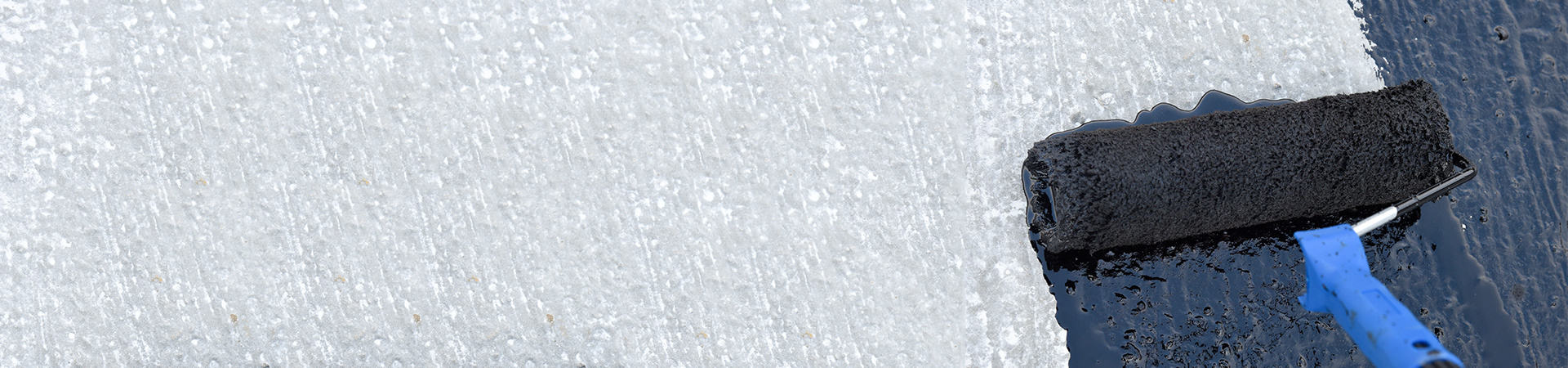

The fire retardant coating is a water-based intumescent fire retardant coating, which has the characteristics of thin layer and highadhesion. The paint can play the role of fire prevention and anti-corrosion when brushed on the surface of the steel structure, and thesurface of the coaling rapidly expands when exposed to fire to form a uniform and dense fire protection and heat insulation layer, so asto achieve the fire protection effect of the steel structure.

Executive standard:GB14907-2018

CONSTRUCTION METHOD

1. Thoroughly remove dust and rust from the surface of the steel structure before construction.

2. The construction should be at a temperature (5-35)'c, and the relative humidity should be controlled within 80%. The steel structureshould not be operated due to condensation, frost and water droplets on ralny days. The construction process should avoid rain aneexposure.The curing time should be prolonged for yellow mold days.

3. After the coating is opened, it should be stired evenly with an electric tool, and then the construction should be carried out aftesuficient stirring. The coating should be able to level and not sag.fthe paint is found to be too thick during construction,it can be dilutecby adding an appropriate amount of water and mixing well before construction.

4. The coaling construcion should be spraying. The coating thickness should be controled at about 1.5mm for thin type and 0.2mm foultra-thin type, subject to no sagging. The next coating can be applied after the surface of the coating is dry.

5. Before the coating is completely dry, it is forbidden to wash with water and rain.

6.Outdoor fireproof coating shall be provided with waterproof protective layer according to normal construction.

| Seriai number | Fire resistance time | Construction thickness | Construction times | Theoretical dosage | lllustrate |

| 1 | 150min | 4.5mm | Ultra thin 10 / thin 4 | 5kg | The thinner the first pass, the better, try tocontrol it to about 0.5mm, about 4 hoursafter the surface is dry, you can apply thesecond pass, after each pass, control it toabout 0.8mm, until the specified thickness. |

| 2 | 120min | 3.3mm | Ultra thin 8 / thin 3 | 4kg | |

| 3 | 90min | 2.4mm | Ultra thin 6 / thin 2 | 3kg | |

| 4 | 60min | 1.5mm | Ultra thin 4 / thin 2 | 2kg |

TECHNICAL INDEX

| State in the container | After stirring, it is in a uniform and delicate state or a thick fluid state,without agglomeration |

| Drying time (surface drying)yh | ≤12 |

| Initial drying and crack resistance | No cracks |

| Bond strength/MPa | ≥0.15 |

| Insulation efficiency deviation | ±15% |

| pH value | ≥7 |

| Water resistance | After the 24h test, the coating should be free of layering, foaming or shedding, and the attenuationof heat insulation efficiency should be ≤35% |

| Resistance to cold and heat cycles | After 15 tests, the coating should be free of cracking, peeling, or blistering, and the attenuation ofthermal insulation efficiency should be ≤35% |

PACKING AND SHIPPING

1.This product is for general cargo transportation.

2.The storage environment temperature is 0-35℃, and it should be stored in a cool, ventilated and dry environment. Protect from rain exposure and frost.

Intumescent fireproof coating for steel structures is a vital solution designed to protect steel from fire damage. This advanced coating expands when exposed to heat, forming a protective char layer that insulates the steel, significantly delaying its exposure to high temperatures. The coating’s ability to create a thermal barrier ensures that steel structures maintain their integrity under extreme conditions, allowing more time for evacuation and preventing catastrophic failure. Ideal for industrial buildings, bridges, and high-rise structures, this fireproof coating provides long-lasting protection, enhancing the safety of both the building and its occupants. The intumescent fireproof coating is easy to apply, ensuring that maintenance is hassle-free and cost-effective while providing high performance in even the most demanding environments. It also helps to meet building regulations and fire safety standards, making it a crucial component in modern construction.

In modern construction, steel structures are widely used for their strength, flexibility, and design versatility. However, steel’s greatest weakness lies in its sensitivity to high temperatures—losing strength rapidly when exposed to fire. To address this critical challenge, quality intumescent fireproof coatings have become the most effective and intelligent solution for ensuring the safety and longevity of steel frameworks. These coatings act as a shield, providing both functional protection and aesthetic value to modern architecture.

A quality intumescent fireproof coating is designed with advanced fire-resistant materials that react under heat. When temperatures rise, the coating undergoes a controlled chemical reaction, expanding up to dozens of times its original thickness. This expansion forms a dense, foam-like carbonized layer that insulates the steel from direct flame and heat exposure. By reducing the rate at which the steel’s temperature increases, the coating delays structural deformation and provides crucial time for evacuation and firefighting efforts. This technology is widely used in high-rise buildings, industrial plants, bridges, tunnels, and public facilities where fire safety is paramount.

The advantages of quality intumescent fireproof coatings go beyond their thermal insulation performance. First, they provide long-term adhesion and durability, ensuring that the protective layer remains stable even under harsh conditions such as humidity, mechanical vibration, and corrosion. Second, they offer excellent decorative effects—the smooth finish and customizable colors allow them to blend seamlessly with the architectural design, eliminating the need for an additional finishing coat. Third, these coatings are easy to apply using standard spraying or brushing methods, making installation efficient and cost-effective.

One of the key benefits of this fireproof coating is its environmental friendliness. Modern formulations are low in volatile organic compounds (VOC) and free from harmful substances, ensuring safe application in both indoor and outdoor environments. This aligns with the growing trend of sustainable and green construction, where safety and environmental performance must coexist.

A recent project provides a perfect example of the coating’s real-world impact. In a large commercial complex, engineers applied a high-quality intumescent fireproof coating to the steel columns and beams of the main structure. During a later fire incident in an adjacent building, the coated structure remained intact despite prolonged exposure to high temperatures. The insulation layer effectively prevented heat from reaching the steel, avoiding collapse and ensuring the building’s stability. This successful case demonstrates not only the coating’s technical effectiveness but also its critical role in preserving life and property.

From an economic standpoint, quality intumescent fireproof coatings also reduce long-term maintenance costs. Unlike conventional fireproof materials that may crack, flake, or require frequent reapplication, high-performance coatings maintain integrity over years of service. Their resistance to corrosion, moisture, and UV exposure helps extend the lifespan of both the coating and the steel structure it protects. For industrial clients, this means fewer shutdowns, lower repair costs, and greater operational reliability.

Ultimately, what makes a quality intumescent fireproof coating stand out is its combination of science, safety, and style. It’s not just about meeting fire codes—it’s about exceeding them, providing peace of mind for architects, engineers, and property owners. With the right coating, a steel structure can maintain its strength, beauty, and stability even in the face of fire. This is why quality intumescent fireproof coatings have become indispensable in today’s safety-conscious construction industry, setting a new benchmark for intelligent, resilient, and sustainable protection.

Previous

Previous

Non-intumescent fire retardant coating

Get a free product quote

*Note: Please be sure to fill in the information accurately and keep the communication open, we will get in touch with you as soon as possible

Guess you might like