Intumescent fireproof paint

Product Classification:

Intumescent fireproof paint

Product Summary:

The construction should be at a temperature (5-35)'c, and the relative humidity should be controlled within 80%.

keywords:

Intumescent fireproof paint

PRODUCT INTRODUCTION

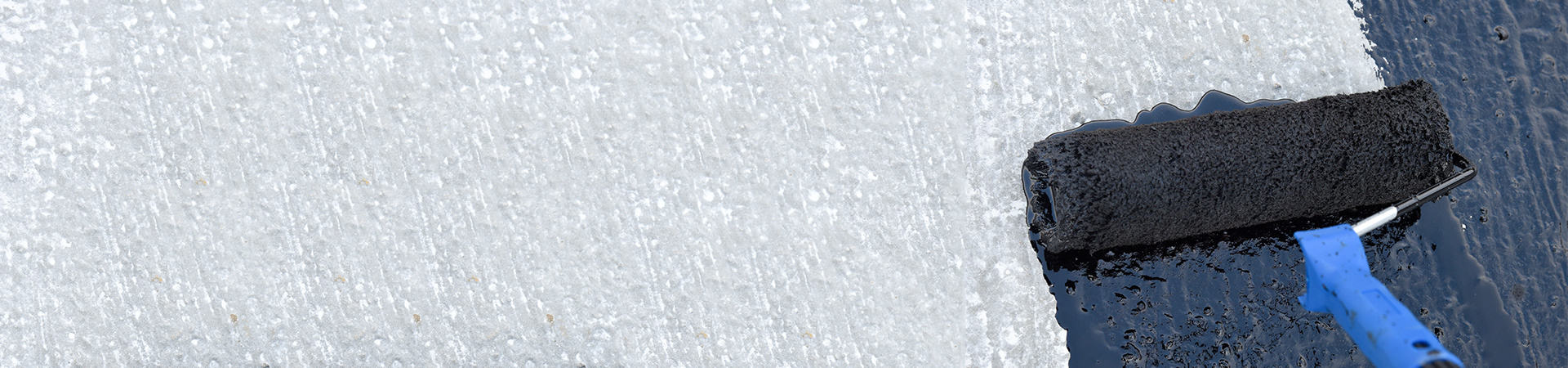

The fire retardant coating is a water-based intumescent fire retardant coating, which has the characteristics of thin layer and highadhesion. The paint can play the role of fire prevention and anti-corrosion when brushed on the surface of the steel structure, and thesurface of the coaling rapidly expands when exposed to fire to form a uniform and dense fire protection and heat insulation layer, so asto achieve the fire protection effect of the steel structure.

Executive standard:GB14907-2018

CONSTRUCTION METHOD

1. Thoroughly remove dust and rust from the surface of the steel structure before construction.

2. The construction should be at a temperature (5-35)'c, and the relative humidity should be controlled within 80%. The steel structureshould not be operated due to condensation, frost and water droplets on ralny days. The construction process should avoid rain aneexposure.The curing time should be prolonged for yellow mold days.

3. After the coating is opened, it should be stired evenly with an electric tool, and then the construction should be carried out aftesuficient stirring. The coating should be able to level and not sag.fthe paint is found to be too thick during construction,it can be dilutecby adding an appropriate amount of water and mixing well before construction.

4. The coaling construcion should be spraying. The coating thickness should be controled at about 1.5mm for thin type and 0.2mm foultra-thin type, subject to no sagging. The next coating can be applied after the surface of the coating is dry.

5. Before the coating is completely dry, it is forbidden to wash with water and rain.

6.Outdoor fireproof coating shall be provided with waterproof protective layer according to normal construction.

| Seriai number | Fire resistance time | Construction thickness | Construction times | Theoretical dosage | lllustrate |

| 1 | 150min | 4.5mm | Ultra thin 10 / thin 4 | 5kg | The thinner the first pass, the better, try tocontrol it to about 0.5mm, about 4 hoursafter the surface is dry, you can apply thesecond pass, after each pass, control it toabout 0.8mm, until the specified thickness. |

| 2 | 120min | 3.3mm | Ultra thin 8 / thin 3 | 4kg | |

| 3 | 90min | 2.4mm | Ultra thin 6 / thin 2 | 3kg | |

| 4 | 60min | 1.5mm | Ultra thin 4 / thin 2 | 2kg |

TECHNICAL INDEX

| State in the container | After stirring, it is in a uniform and delicate state or a thick fluid state,without agglomeration |

| Drying time (surface drying)yh | ≤12 |

| Initial drying and crack resistance | No cracks |

| Bond strength/MPa | ≥0.15 |

| Insulation efficiency deviation | ±15% |

| pH value | ≥7 |

| Water resistance | After the 24h test, the coating should be free of layering, foaming or shedding, and the attenuationof heat insulation efficiency should be ≤35% |

| Resistance to cold and heat cycles | After 15 tests, the coating should be free of cracking, peeling, or blistering, and the attenuation ofthermal insulation efficiency should be ≤35% |

PACKING AND SHIPPING

1.This product is for general cargo transportation.

2.The storage environment temperature is 0-35℃, and it should be stored in a cool, ventilated and dry environment. Protect from rain exposure and frost.

As global construction standards continue to evolve, the need for advanced fire protection materials that combine safety, durability, and design flexibility has become paramount. Among these innovations, durable intumescent fireproof paint stands out as a revolutionary solution that ensures long-term structural integrity while enhancing architectural freedom. Designed for high-performance fire resistance and long-lasting surface protection, this coating serves as an invisible shield for steel, wood, and concrete, preserving both lives and property in critical environments.

Durable intumescent fireproof paint represents a significant evolution in passive fire protection technology. Its function goes beyond simple coating—it is a reactive system engineered to protect structural materials when exposed to extreme heat or open flames. Upon reaching a certain temperature, the paint expands to many times its original thickness, forming a dense, insulating carbonaceous layer that prevents heat from reaching the underlying material. This transformation delays temperature rise and maintains the structural stability of steel or other substrates, providing valuable time for evacuation and fire control.

The true advantage of this coating lies in its durability. Traditional fireproof coatings may deteriorate over time due to exposure to moisture, temperature fluctuations, or chemical contaminants. However, durable intumescent fireproof paint is formulated with advanced polymer resins, corrosion inhibitors, and weather-resistant binders that ensure a stable protective performance even after years of service. This long-term resilience makes it ideal for projects that demand both reliability and minimal maintenance, such as high-rise buildings, tunnels, industrial facilities, power plants, and transportation hubs.

In modern architecture, safety should never come at the cost of aesthetics. One of the major benefits of durable intumescent fireproof paint is its thin and smooth film thickness, which preserves the natural beauty of the structure. Unlike traditional cementitious coatings that are bulky and prone to cracking, this paint offers superior protection with a refined finish. It can be tinted to various colors or applied beneath decorative topcoats, allowing architects and designers to achieve visual harmony without compromising fire safety performance.

From a technical standpoint, the coating’s performance is based on a highly stable chemical system. It integrates organic and inorganic components that react predictably when subjected to heat. During a fire, the intumescent additives within the coating expand rapidly, producing a foamed char barrier that effectively reflects heat radiation and slows oxygen penetration. At the same time, anti-corrosive elements within the base layer protect the steel from oxidation, ensuring that the material remains structurally sound even after the incident.

In addition to fire resistance, the coating also provides excellent protection against corrosion, humidity, and UV degradation. This multi-functional capability is especially important in offshore structures, chemical plants, or outdoor architectural projects where environmental stress can weaken conventional coatings. Durable intumescent fireproof paint withstands such challenges with ease, reducing long-term maintenance costs and ensuring continuous protection under the harshest conditions.

One of the key applications of durable intumescent fireproof paint is in steel structure protection. Steel, though strong and versatile, loses its load-bearing capacity rapidly when exposed to high temperatures—usually above 550°C. By applying this coating, the steel can maintain its strength for up to 2 hours or more, depending on the system thickness and application method. This extended resistance period not only helps structures comply with fire safety standards but also provides peace of mind to property owners and occupants.

Its application process is straightforward and efficient. The coating can be applied via airless spray, brush, or roller, adapting to both large industrial installations and smaller architectural details. With excellent adhesion and fast-drying properties, it forms a uniform film that adheres strongly to various substrates. Its low-VOC, non-toxic formulation meets modern environmental and safety regulations, making it suitable for both new construction and renovation projects.

In real-world use, this coating has demonstrated exceptional performance. For example, in a petrochemical facility, durable intumescent fireproof paint was applied to steel frameworks and storage tanks. After years of operation in a highly corrosive and humid environment, the coating maintained both its adhesion and its protective properties. In another case, a metropolitan subway tunnel utilized this coating to protect its concrete linings and support beams, achieving both fireproofing and long-term resistance to vibration and moisture. Such examples highlight how the product provides dependable safety across diverse industries.

Another critical area where this coating excels is cost efficiency. While the initial investment may appear slightly higher than traditional coatings, the total life-cycle cost is significantly lower. Thanks to its durability and low maintenance requirements, it eliminates frequent recoating cycles, minimizing labor and downtime expenses. For project developers and facility managers, this long-term economic benefit makes it a highly valuable choice.

Durable intumescent fireproof paint also solves multiple pain points faced by engineers and contractors. It replaces heavy fireproofing materials with a lightweight, easy-to-apply solution that doesn’t overload the structure. It dries faster, allowing construction schedules to proceed without delay. It performs equally well in interior and exterior environments, removing the need for separate products for different areas. And most importantly, it ensures that safety compliance is achieved with confidence and reliability.

In terms of certification, the product complies with international fire protection standards including ASTM, EN, and UL classifications. It has been tested for adhesion, impact resistance, corrosion protection, and fire endurance, consistently achieving excellent results. By meeting or exceeding these standards, durable intumescent fireproof paint provides the assurance that every project built with it meets the highest levels of safety and regulatory requirements.

Moreover, sustainability is an integral part of its design philosophy. Modern construction is shifting toward eco-conscious materials, and this coating is formulated with environmentally friendly resins and solvents. It emits low levels of volatile organic compounds (VOC), supports green building certifications, and aligns with global trends toward safer and cleaner construction practices.

As industries continue to innovate, the demand for coatings that combine advanced protection, long-term performance, and environmental responsibility will only increase. Durable intumescent fireproof paint represents the future of passive fire protection—an intelligent solution that not only guards against disaster but also enhances the longevity and aesthetics of the structure.

In summary, durable intumescent fireproof paint is more than a surface coating—it is a comprehensive safety system. It provides robust fire resistance, outstanding durability, and environmental resilience while maintaining design flexibility. By offering long-term value, simplified application, and compliance with strict international standards, it helps architects, engineers, and building owners achieve true peace of mind. In every sense, it is the perfect fusion of science, safety, and sustainability—an enduring guardian for modern architecture and industry alike.

Previous

Indoor intumescent fireproof coating

Get a free product quote

*Note: Please be sure to fill in the information accurately and keep the communication open, we will get in touch with you as soon as possible

Guess you might like