Non-intumescent fire retardant coating

Product Classification:

Intumescent fireproof paint

Product Summary:

The paint can play the role of fire prevention and anti-corrosion when brushed on the surface

keywords:

Non-intumescent fire retardant coating

Non-intumescent fire retardant coating

PRODUCT INTRODUCTION

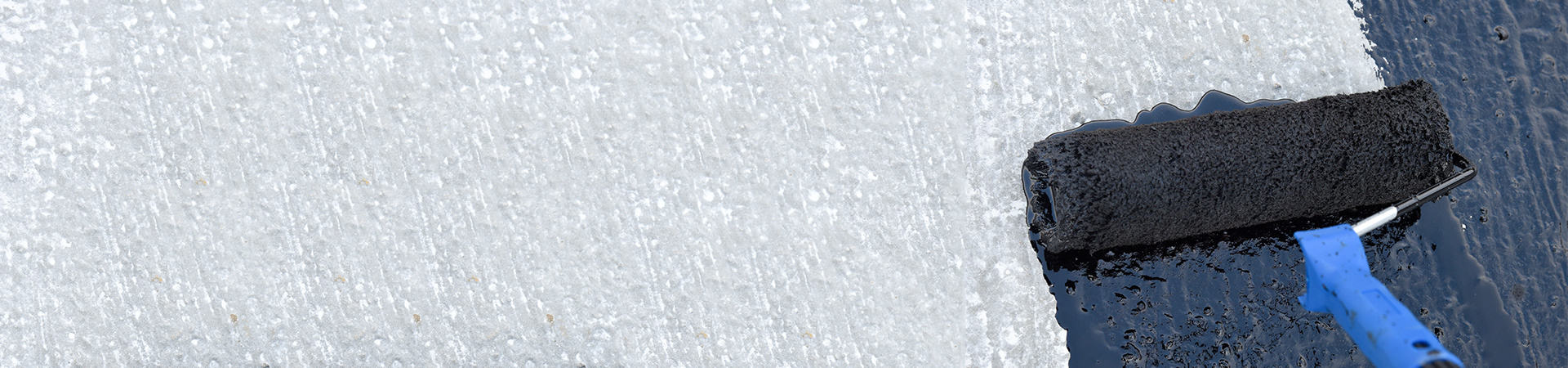

The fire retardant coating is a water-based intumescent fire retardant coating, which has the characteristics of thin layer and highadhesion. The paint can play the role of fire prevention and anti-corrosion when brushed on the surface of the steel structure, and thesurface of the coaling rapidly expands when exposed to fire to form a uniform and dense fire protection and heat insulation layer, so asto achieve the fire protection effect of the steel structure.

Executive standard:GB14907-2018

CONSTRUCTION METHOD

1. Thoroughly remove dust and rust from the surface of the steel structure before construction.

2. The construction should be at a temperature (5-35)'c, and the relative humidity should be controlled within 80%. The steel structureshould not be operated due to condensation, frost and water droplets on ralny days. The construction process should avoid rain aneexposure.The curing time should be prolonged for yellow mold days.

3. After the coating is opened, it should be stired evenly with an electric tool, and then the construction should be carried out aftesuficient stirring. The coating should be able to level and not sag.fthe paint is found to be too thick during construction,it can be dilutecby adding an appropriate amount of water and mixing well before construction.

4. The coaling construcion should be spraying. The coating thickness should be controled at about 1.5mm for thin type and 0.2mm foultra-thin type, subject to no sagging. The next coating can be applied after the surface of the coating is dry.

5. Before the coating is completely dry, it is forbidden to wash with water and rain.

6.Outdoor fireproof coating shall be provided with waterproof protective layer according to normal construction.

| Seriai number | Fire resistance time | Construction thickness | Construction times | Theoretical dosage | lllustrate |

| 1 | 150min | 4.5mm | Ultra thin 10 / thin 4 | 5kg | The thinner the first pass, the better, try tocontrol it to about 0.5mm, about 4 hoursafter the surface is dry, you can apply thesecond pass, after each pass, control it toabout 0.8mm, until the specified thickness. |

| 2 | 120min | 3.3mm | Ultra thin 8 / thin 3 | 4kg | |

| 3 | 90min | 2.4mm | Ultra thin 6 / thin 2 | 3kg | |

| 4 | 60min | 1.5mm | Ultra thin 4 / thin 2 | 2kg |

TECHNICAL INDEX

| State in the container | After stirring, it is in a uniform and delicate state or a thick fluid state,without agglomeration |

| Drying time (surface drying)yh | ≤12 |

| Initial drying and crack resistance | No cracks |

| Bond strength/MPa | ≥0.15 |

| Insulation efficiency deviation | ±15% |

| pH value | ≥7 |

| Water resistance | After the 24h test, the coating should be free of layering, foaming or shedding, and the attenuationof heat insulation efficiency should be ≤35% |

| Resistance to cold and heat cycles | After 15 tests, the coating should be free of cracking, peeling, or blistering, and the attenuation ofthermal insulation efficiency should be ≤35% |

PACKING AND SHIPPING

1.This product is for general cargo transportation.

2.The storage environment temperature is 0-35℃, and it should be stored in a cool, ventilated and dry environment. Protect from rain exposure and frost.

Our Non-intumescent fire retardant coating offers advanced protection for a variety of materials, ensuring safety and durability in high-risk environments. Designed to provide reliable fire resistance without the expansion or bubbling effects of traditional intumescent coatings, our Non-intumescent fire retardant coating is the ideal choice for applications where minimal aesthetic disruption and ease of application are important.

This Non-intumescent fire retardant coating is formulated to prevent the spread of flames by forming a protective barrier on the surface of treated materials. It maintains the structural integrity of materials, such as wood, metal, and plastics, without altering their appearance. The coating is perfect for use in both commercial and residential buildings, as well as industrial settings that require high-performance fire protection.

One of the standout features of our Non-intumescent fire retardant coating is its ability to withstand extreme temperatures without losing effectiveness. Unlike traditional coatings that expand when exposed to heat, this product remains stable, ensuring long-lasting fire protection even in the harshest conditions. It is also resistant to weathering, UV rays, and other environmental factors, making it suitable for both indoor and outdoor applications.

As global fire safety standards continue to rise, architects, engineers, and builders are seeking more advanced, durable, and eco-friendly fire protection solutions. Among these innovations, the newest non-intumescent fire retardant coating has emerged as a breakthrough technology, redefining how modern infrastructure defends itself against fire hazards. Unlike traditional intumescent coatings that rely on expansion under heat, this non-intumescent system prevents combustion at the molecular level, providing stable, long-term, and maintenance-free protection for a wide variety of structural materials.

The newest non-intumescent fire retardant coating operates through a unique mechanism. Instead of expanding or foaming when exposed to flames, it forms a thermally stable barrier that resists ignition and slows down the spread of fire. The advanced formulation contains flame inhibitors, thermal stabilizers, and ceramic compounds that interact to suppress heat transfer and oxygen diffusion. This means that even in extreme temperatures, the coating retains its mechanical integrity and continues to protect the substrate beneath. It’s an innovation that turns passive materials into active fire-resistant systems.

One of the most remarkable features of this coating is its versatility. It can be applied to a wide range of materials, including steel, aluminum, wood, concrete, and composite surfaces. For steel structures, it preserves mechanical strength under heat and prevents rapid temperature escalation. For wooden and polymer-based materials, it creates a protective shield that reduces charring and minimizes smoke generation. Whether in industrial facilities, residential buildings, or transportation systems, the newest non-intumescent coating ensures comprehensive safety across multiple environments.

Durability is another core advantage. Traditional fireproof coatings often suffer from cracking, flaking, or losing effectiveness over time due to environmental exposure. In contrast, the newest non-intumescent formulation provides superior adhesion, UV resistance, and corrosion protection. It can withstand moisture, chemical vapors, and temperature fluctuations, making it ideal for both indoor and outdoor applications. This long-lasting performance not only guarantees consistent safety but also reduces maintenance costs—an essential factor for large-scale projects with demanding operational lifespans.

Beyond performance, the coating is designed with sustainability in mind. Developed using low-VOC, solvent-free, and halogen-free materials, it meets the strictest environmental regulations while ensuring safe application and minimal impact on air quality. This makes it particularly suitable for projects requiring green certifications or environmental compliance. In addition, its smooth, decorative finish allows it to double as a final aesthetic layer, eliminating the need for an additional topcoat. Engineers and designers appreciate that it combines safety and style without compromise.

In terms of application, the coating process is both efficient and flexible. It can be sprayed, brushed, or rolled onto surfaces with standard equipment, offering uniform coverage and rapid drying. Its excellent surface bonding properties ensure that even complex geometries—such as curved beams, joints, or confined mechanical spaces—are fully protected. This efficiency translates into faster installation, lower labor costs, and minimal downtime during construction or retrofitting.

Real-world applications have already demonstrated the reliability of this technology. In a recent energy infrastructure project, the newest non-intumescent fire retardant coating was used on power plant equipment and steel frameworks. During testing, it successfully resisted temperatures exceeding 1000°C without degradation or delamination, maintaining the structural integrity of critical components. In another case, it was applied to the interior surfaces of a logistics warehouse, where its low smoke emission and clean finish ensured both safety and compliance with fire codes. These results prove that the coating performs consistently in the toughest conditions—making it a trusted choice for safety-driven industries.

The newest non-intumescent fire retardant coating also addresses key pain points faced by architects and maintenance teams. Conventional intumescent coatings often require thick layers, long curing times, and frequent reapplication, which increase project costs and complexity. The new generation non-intumescent product solves these problems with thin, uniform application and superior longevity. It also prevents surface discoloration or bubbling, ensuring that the aesthetic integrity of modern architecture is preserved. Clients benefit from both technical protection and visual quality, without trade-offs.

From a safety management perspective, adopting this advanced coating enhances compliance with international fire protection standards such as UL, EN, and ISO. It reduces insurance risk, minimizes fire damage liability, and helps achieve long-term operational resilience. Industries such as energy, aviation, transportation, warehousing, and civil construction are rapidly integrating this technology into their safety systems. For governments and corporate owners, it represents not only compliance but confidence—knowing that their structures are safeguarded by the most advanced coating science available today.

In essence, the newest non-intumescent fire retardant coating represents a paradigm shift in fire protection. By combining scientific innovation, environmental responsibility, and practical design flexibility, it delivers a complete solution for the modern world’s safety challenges. It replaces outdated, reactive coatings with a smarter, more stable, and sustainable form of defense—ensuring that buildings, equipment, and people remain safe in the face of fire. It is not just a coating; it is the next generation of intelligent fire protection technology, setting a new global benchmark for reliability, performance, and peace of mind.

Previous

Intumescent fireproof paint

Get a free product quote

*Note: Please be sure to fill in the information accurately and keep the communication open, we will get in touch with you as soon as possible

Guess you might like