Non-intumescent fire retardant coating

Product Classification:

Intumescent fireproof paint

Product Summary:

The paint can play the role of fire prevention and anti-corrosion when brushed on the surface

keywords:

Non-intumescent fire retardant coating

PRODUCT INTRODUCTION

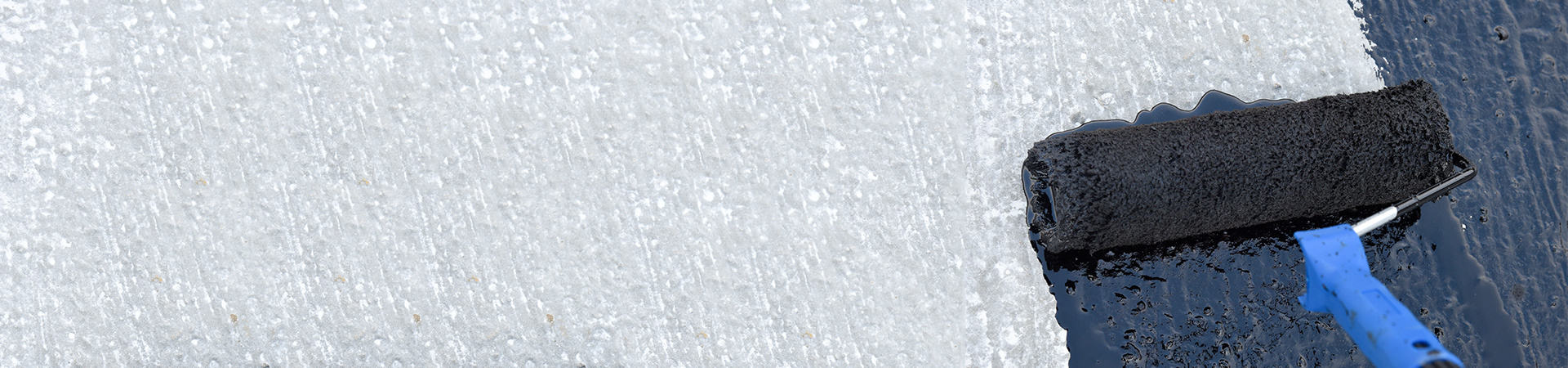

The fire retardant coating is a water-based intumescent fire retardant coating, which has the characteristics of thin layer and highadhesion. The paint can play the role of fire prevention and anti-corrosion when brushed on the surface of the steel structure, and thesurface of the coaling rapidly expands when exposed to fire to form a uniform and dense fire protection and heat insulation layer, so asto achieve the fire protection effect of the steel structure.

Executive standard:GB14907-2018

CONSTRUCTION METHOD

1. Thoroughly remove dust and rust from the surface of the steel structure before construction.

2. The construction should be at a temperature (5-35)'c, and the relative humidity should be controlled within 80%. The steel structureshould not be operated due to condensation, frost and water droplets on ralny days. The construction process should avoid rain aneexposure.The curing time should be prolonged for yellow mold days.

3. After the coating is opened, it should be stired evenly with an electric tool, and then the construction should be carried out aftesuficient stirring. The coating should be able to level and not sag.fthe paint is found to be too thick during construction,it can be dilutecby adding an appropriate amount of water and mixing well before construction.

4. The coaling construcion should be spraying. The coating thickness should be controled at about 1.5mm for thin type and 0.2mm foultra-thin type, subject to no sagging. The next coating can be applied after the surface of the coating is dry.

5. Before the coating is completely dry, it is forbidden to wash with water and rain.

6.Outdoor fireproof coating shall be provided with waterproof protective layer according to normal construction.

| Seriai number | Fire resistance time | Construction thickness | Construction times | Theoretical dosage | lllustrate |

| 1 | 150min | 4.5mm | Ultra thin 10 / thin 4 | 5kg | The thinner the first pass, the better, try tocontrol it to about 0.5mm, about 4 hoursafter the surface is dry, you can apply thesecond pass, after each pass, control it toabout 0.8mm, until the specified thickness. |

| 2 | 120min | 3.3mm | Ultra thin 8 / thin 3 | 4kg | |

| 3 | 90min | 2.4mm | Ultra thin 6 / thin 2 | 3kg | |

| 4 | 60min | 1.5mm | Ultra thin 4 / thin 2 | 2kg |

TECHNICAL INDEX

| State in the container | After stirring, it is in a uniform and delicate state or a thick fluid state,without agglomeration |

| Drying time (surface drying)yh | ≤12 |

| Initial drying and crack resistance | No cracks |

| Bond strength/MPa | ≥0.15 |

| Insulation efficiency deviation | ±15% |

| pH value | ≥7 |

| Water resistance | After the 24h test, the coating should be free of layering, foaming or shedding, and the attenuationof heat insulation efficiency should be ≤35% |

| Resistance to cold and heat cycles | After 15 tests, the coating should be free of cracking, peeling, or blistering, and the attenuation ofthermal insulation efficiency should be ≤35% |

PACKING AND SHIPPING

1.This product is for general cargo transportation.

2.The storage environment temperature is 0-35℃, and it should be stored in a cool, ventilated and dry environment. Protect from rain exposure and frost.

Our Non-intumescent fire retardant coating offers advanced protection for a variety of materials, ensuring safety and durability in high-risk environments. Designed to provide reliable fire resistance without the expansion or bubbling effects of traditional intumescent coatings, our Non-intumescent fire retardant coating is the ideal choice for applications where minimal aesthetic disruption and ease of application are important.

This Non-intumescent fire retardant coating is formulated to prevent the spread of flames by forming a protective barrier on the surface of treated materials. It maintains the structural integrity of materials, such as wood, metal, and plastics, without altering their appearance. The coating is perfect for use in both commercial and residential buildings, as well as industrial settings that require high-performance fire protection.

One of the standout features of our Non-intumescent fire retardant coating is its ability to withstand extreme temperatures without losing effectiveness. Unlike traditional coatings that expand when exposed to heat, this product remains stable, ensuring long-lasting fire protection even in the harshest conditions. It is also resistant to weathering, UV rays, and other environmental factors, making it suitable for both indoor and outdoor applications.

Previous

Intumescent fireproof paint

Get a free product quote

*Note: Please be sure to fill in the information accurately and keep the communication open, we will get in touch with you as soon as possible

Guess you might like