Cable fire retardant coating

Product Classification:

Intumescent fireproof paint

Product Summary:

MY cable fireproof coating is a new type of fireproof coating successfully developed by our company in accordance with theGB28374-2012 national standard.

keywords:

Cable fire retardant coating

PRODUCT INTRODUCTION

MY cable fireproof coating is a new type of fireproof coating successfully developed by our company in accordance with theGB28374-2012 national standard. The coating of this product can form a uniform and dense sponge-like foam insulation layer whenexposed to fire, which can efectively inhibit and block the spread of flames, Spread and protect wires and cables.ts main advanages are.environmental prolection, non-polluting, non-toxic and tasteless, and does not pose a threat to the health of the applicator. This produclalso has the characteristics of thin coaing, strong adhesion, good fexibilty, et., and has good insulaion and anti-corrosion functions.

Executive standard: GB28374-2012

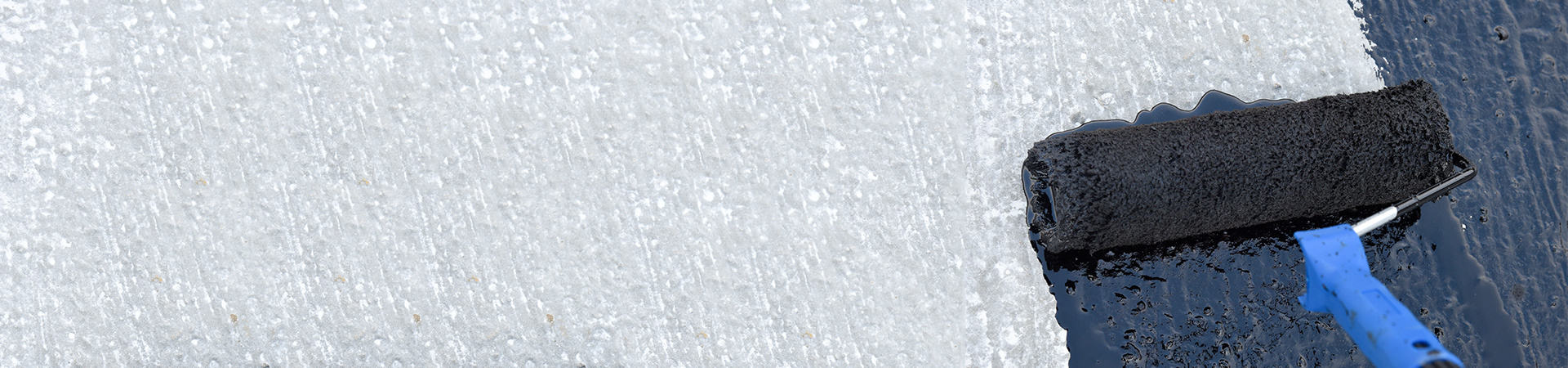

CONSTRUCTION METHOD

1. The floating dust, oil stains and debris on the surface of the cable should be cleaned and polished before the construction of thefireproof coating. The construction of the fireproof coating can be carried out after the surface is dry.

2. The construction of this product adopts spraying, brushing and other methods. 1t should be fully stirred during use. When the painis slightly thicker, an appropriate amount of supporting diluent can be added to dilute it to facilitate spraying.

3. During the construction process and before the coating is dry, it should be waterproof, anti-exposure, ani-pollution, anti.movement,anti-bending, and repair in time if it is damaged.

4. For cables and cables with plastic and rubber sheaths, it is usually directly painted more than 5 times, the thickness of the coatingis 0.5-fmm, and the amount is about 1.5kg/m2. For high-quality insulated cables, they should be covered with a layer of glass clothAnd then paint, if it is applied outdoors or in a damp environment, a matching overcoat varnish should be added.

TECHNICAL INDEX

| State in the container | After stirring, it is in a delicate state |

| Fineness | ≤90um |

| Viscosity | ≥70s |

| Drying time | Surface dry≤4h actual dry≤24h |

| Oil resistance | There is no wrinkle, peeling or blistering of the coating after immersing for 7 days |

| Salt water resistance | There is no wrinkle, peeling or blistering of the coating after immersing for 7 days |

| Humidity resistance | After 7d test, the coating is free of wrinkle, peeling and blistering |

| Freeze thaw cycle resistance | After 15 cycles, the coating is free of wrinkle, peeling and blistering |

| Bending resistance | The coating shall be free of delamination, falling off and peeling |

| Flame retardancy | Carbonization height ≤ 2.50M |

PACKING AND SHIPPING

1. This product is packed in metal or plastic drums.

2. The product should be stored in a cool, dry and ventilated environment.

3. When the product is transported, t should be protected from sunlight, rain,frost, and open fame, and prevent the packaging barel from being damaged, dumped, or overflowed.

4.The efective storage period of this product is 6 months

Next

Previous

Fireproof pillow

Next

Get a free product quote

*Note: Please be sure to fill in the information accurately and keep the communication open, we will get in touch with you as soon as possible

Guess you might like