Indoor non-intumescent fire retardant coating for steel structure

Product Classification:

Intumescent fireproof paint

Product Summary:

The fire relardant coating is a water-based intumescent fire relardant coating, which has the characteristics of thin layer and highadhesion.

keywords:

New Non-Intumescent Fire Retardant Coating

Indoor non-intumescent fire retardant coating for steel structure

PRODUCT INTRODUCTION

The fire retardant coating is a two-component heat insulating fire retardant coaing.When the coaling encounters a fire,a glaze layer isformed on the fire site for heat insulation and fire prevention, so as to achieve the fire protection effect of the steel structure.

Executive standard:GB14907-2018

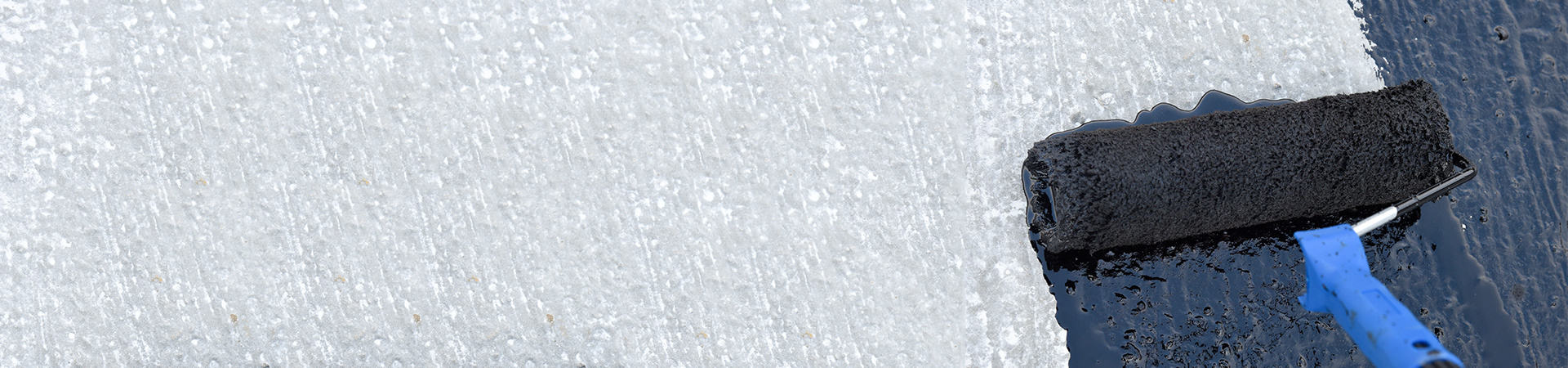

CONSTRUCTION METHOD

1. Thoroughly remove dust and rust from the surface of the steel structure before construction.

2. The construction should be at a temperature (5-35)'c, and the relative humidity should be controlled within 80%, The steel structureshould not be operated due to condensalion, frost and water droplels on rainy days. The construction process should avoid rain andexposure.The curing time should be prolonged for yellow mold days.

3. After the coating is opened, it should be stirred evenly with an electric tool, and then the construction should be carried out afersuficient stirring. The coaing should be able to level and not sag.lfthe paint is found to be too thick during construction,it can be dilutedby adding an appropriate amount of water and mixing well before construction

4. The coating construction should be spraying. The coaing thickness should be controlled at about 1.5mm for thin type and 0.2mm forultra-thin type, subject to no sagging. The next coating can be applied after the surface of the coating is dry.

5. Before the coating is completely dry, it is forbidden to wash with water and rain.

Nole: At the construction site, there should not be too many ingredients at a time. Generally, use as much as you want to prevent failure

It is best to use it up in 30 minutes before using it again.

| Seriai number | Fire resistance time | Construction thickness | Construction times | lllustrate |

| 1 | 180min | 32mm | 5 all over |

The primer shall be roughened first and sprayed with styrene acrylic lotion or 707 glue with a thickness not exceeding 1mm,Each construction is subject to non-sagging, and the next pass can be carried out after the coating surface is dry, and each pass is controlled at about 6mm until the thickness required by the design is reached. |

| 2 | 150min | 26mm | 5 all over | |

| 3 | 120min | 20mm | 5 all over |

TECHNICAL INDEX

| State in the container | After stirring, it is in a uniform and delicate state or a thick fluid state,without agglomeration |

| Drying time (surface dryingy)/h | ≤24 |

| Initial drying and crack resistance | 1~3 cracks are allowed, and the width should be s0.5mm |

| Bond strength/MPa | ≥0.04 |

| Compressive strength√MPa | ≥0.3 |

| Dry density/(kg/m3) | ≤500 |

| Insulation efficiency deviation | ±15% |

| Insulation efficiency deviation | ≥7 |

| Water resistance | After the 24h test, the coating should be free of layering, foaming or shedding, and the attenuationof heat insulation efficiency should be ≤35% |

| Resistance to cold and heat cycles | After 15 tests, the coating should be free of cracking, peeling, or blistering,and the attenuation ofthermal insulation effciency should be ≤35% |

PACKING AND SHIPPING

1.This product is for general cargo transportation.

2.The powder material of this product is protected from rain, and the liquid material is anl-freeze and anti-exposure. lt should be stored in a cool.well-vntilated,dry environment.

The Indoor Non-Intumescent Fire Retardant Coating for Steel Structure is specially formulated to provide reliable fire protection without expanding under heat. This advanced coating enhances the fire resistance of steel structures in indoor environments while maintaining a clean and smooth finish. Designed for easy application and long-lasting performance, the indoor non-intumescent fire retardant coating for steel structure ensures stability and safety in commercial, industrial, and residential buildings. It adheres strongly to steel surfaces and resists cracking, peeling, and aging. The coating helps delay heat transfer to the steel, reducing structural risk in fire scenarios. With low VOC content and excellent adhesion, the indoor non-intumescent fire retardant coating for steel structure is environmentally friendly and ideal for enclosed spaces where aesthetics and fire safety are equally important.

Previous

Tunnel fire retardant coating

Get a free product quote

*Note: Please be sure to fill in the information accurately and keep the communication open, we will get in touch with you as soon as possible

Guess you might like