Tunnel fire retardant coating

Product Classification:

Intumescent fireproof paint

Product Summary:

The tunnel freproof coating is a non-expandable heat-insulating coating with light densily, low thermal conductivity and good fire resistance.

keywords:

Durable Tunnel Fire Retardant Coating

Tunnel fire retardant coating

PRODUCT INTRODUCTION

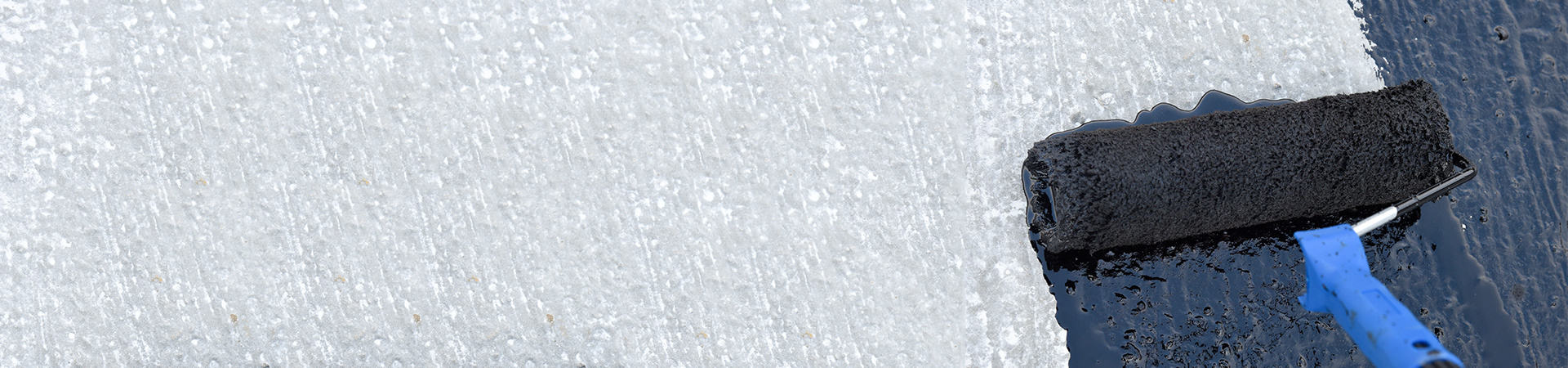

The tunnel freproof coating is a non-expandable heat-insulating coating with light densily, low thermal conductivity and good fire resistance. lt is also a pollution-free water-based paint that can be sprayed on concrete surfaces such as highways, railways,and tunnels bymechanical soraving, Basicaly no dense smoke and loxic gases are produced during a fire. The coaling is 20mm and the fre resislancelimit exceeds 2.0h.

Executive standard: GB28375-2012

CONSTRUCTION METHOD

1. Scope: This coating can be sprayed or manally applied to the surface of concrete such as highways, railways, tunnels, etc. andcan also be used in culverts of underground railways to increase its fire resistance limit to more than 2.0h. Under no fire conditionsthis coating can also absorb sound.

2. General conditions for construction, room temperature> 0℃ above, humidity <90%, wind force <level 4. When the constuctiontemperature is below 0℃, it is necessary to add antifreeze to the factory. When the wind force is greater than level 4, it needs to be

sheltered slightly.

3. Base surface treatment: remove oil, float and sink, and remove water droplets, To achieve a clean surface, when the surface ofthe concrete is too smooth, measures such as roughening can be taken on the surface.

4. The spraying thickness of the first layer is 2mm, and the thickness of each subseguent layer is 6-8mm until the reguired thicknessis reached. The second layer can be sprayed only after the first layer is completely dry.

5. in the case of minor repairs, a spatula can be used for patching, Genraly, the spatula method is not suitable for large-areaconstuction.

6. Matters needing attention: Do not flush with water when the coating is not completely dry.TECHNICAL INDEX

| State in the container | After stirring, it becomes a uniform thick liquid without lumps |

| Drying schedule | ≤24h |

| Bonding strength | ≤0.15Mpa |

| Dry density | ≤700kg/m3 |

| Water resistance | ≥720h, the coating will not crack, layer or fall off, and allow slight swelling and discoloration |

| Acid resistance | ≥360h, the coating will not crack, layer or fall off, and allow slight swelling and discoloration |

| Alkali resistance | ≥360h, the coating will not crack, layer or fall off, and allow slight swelling and discoloration |

| Humidity and heat resistance | ≥2720h, the coating will not crack, layer or fall off, and allow slight swelling and discoloration |

| Freeze thaw cycle test | ≥15, the coating will not crack, layer, fall off, and allow slight swelling and discoloration |

| Smoke producing property | ZA1 |

| Fire resistance | 2.0h |

PACKING AND SHIPPING

1.General cargo transportation.

2. Store in a cool, ventilated and dry environment at 0-35℃ to prevent rain and sun exposure.

Previous

Decorative type fire retardant coating

Get a free product quote

*Note: Please be sure to fill in the information accurately and keep the communication open, we will get in touch with you as soon as possible

Guess you might like